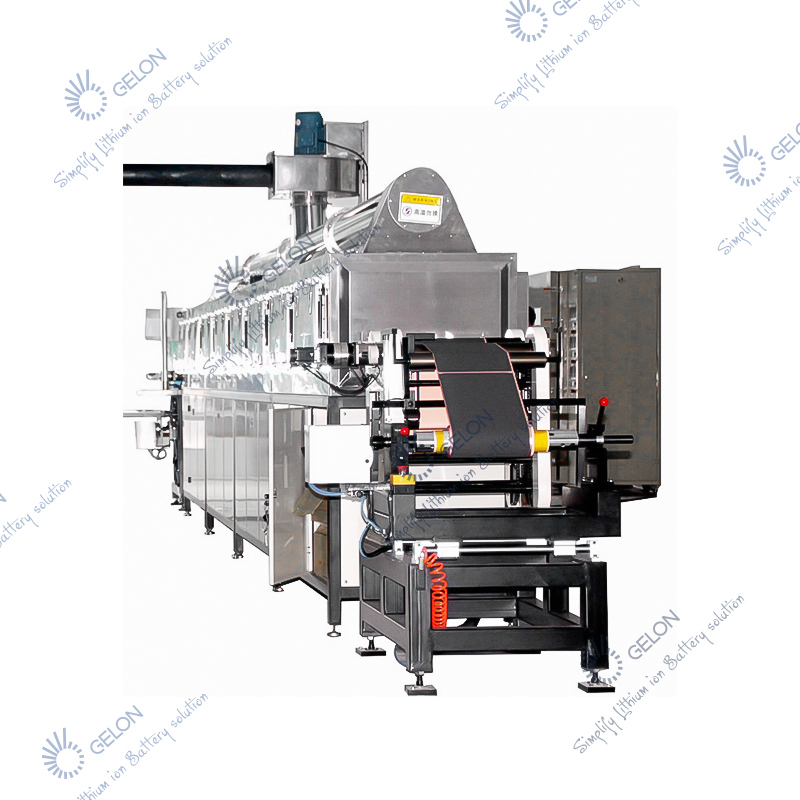

Automatic Slot Die Coating Machine

5.0

Read 800 reviewsEquipment use: Fully automatic coating machine for battery cathode and anode electrode making , suitable for a variety of material systems.Equipment features: adopt imported extrusion die head; die head position adopts high-precision servo full closed loop control; oven uses electric heating anti-ri

17 people are viewing this right now

Equipment use: Fully automatic coating machine for battery cathode and anode electrode making , suitable for a variety of material systems.

Equipment features: adopt imported extrusion die head; die head position adopts high-precision servo full closed loop control; oven uses electric heating anti-riot oven (positive electrode), each oven door has a perspective window; electrode tension control, constant tension release roll, constant tension coating, drying, taper tension winding; centralized control of system parameters, human-machine interface adopts touch screen and button mode, hierarchical control, process parameters can be locked, stored and recalled.

Specifications:

1) Foil specifications:

Thickness: Aluminum foil (AL): 11~30μm. Copper foil (Cu): 6~30μm

Width: Aluminum foil (AL): 300-680mm Copper foil (Cu): 300-680mm

2) Slurry viscosity: 1500~20000 cps

3) Coating thickness: 50-150um (single side dry thickness)

4) Coating width: maximum 650mm

5) Mechanical speed: 2-50m/min

6) Oven: 3m/zone, a total of 12 zones

7) Temperature in the drying tunnel: 70-150℃