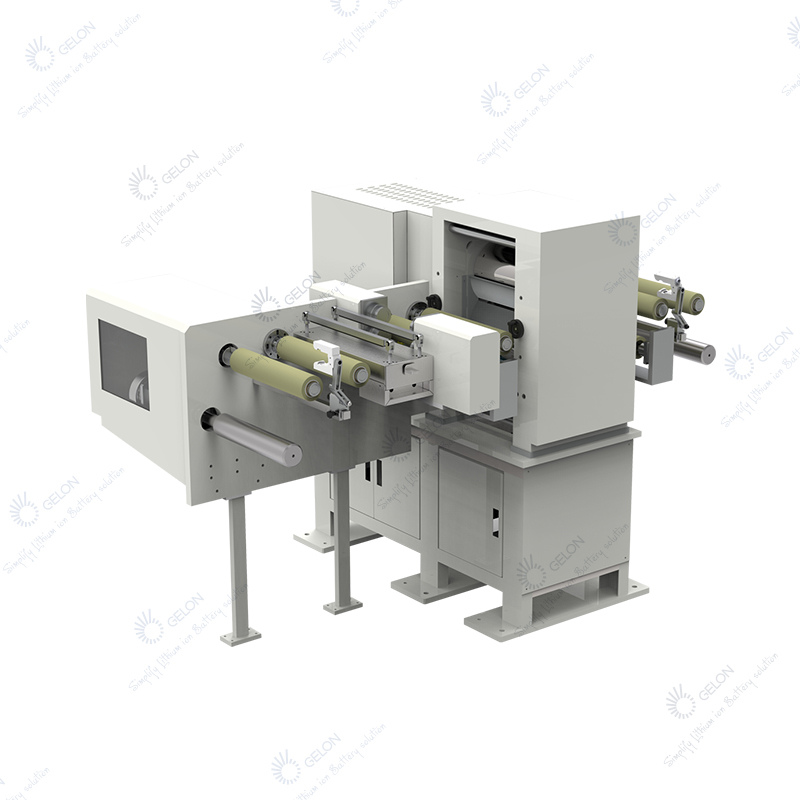

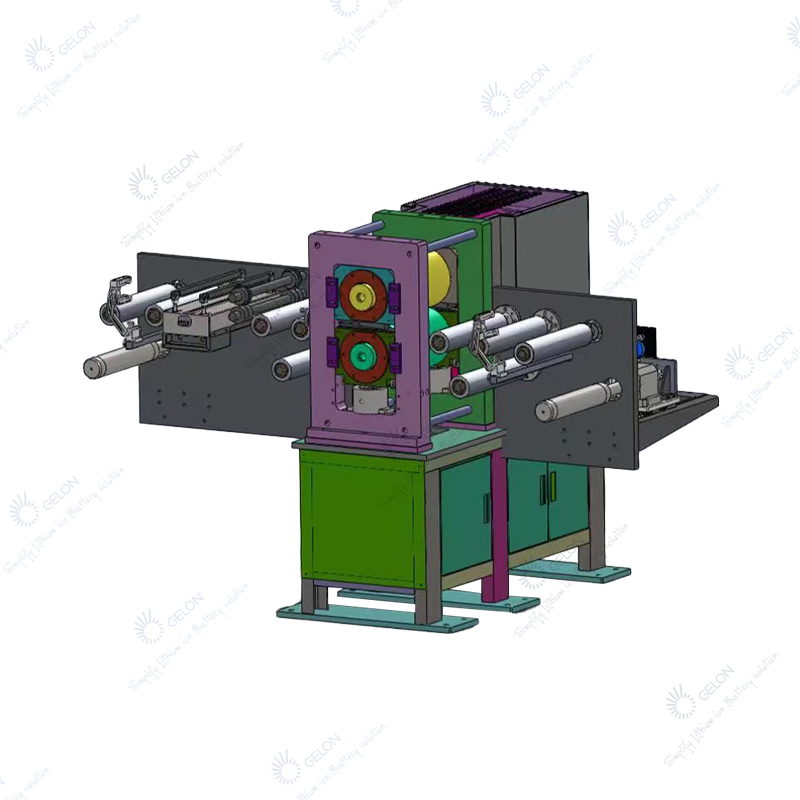

Roller machine Φ210×330mm/80T

5.0

Read 435 reviewsIntroduction:The rolling mill is the main equipment in the continuous rolling production line. It consists of cast steel gantry frame, rolls, frequency conversion motor reducer, gap adjustment system, electrical control system, feeding guard plate and roll surface cleaning mechanism.The main functio

17 people are viewing this right now

Introduction:

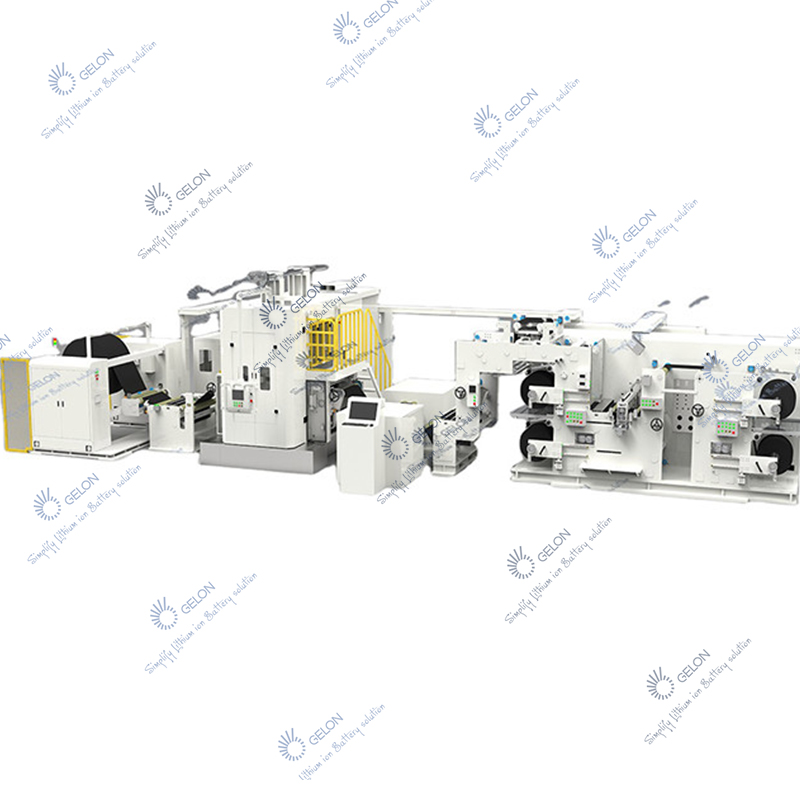

The rolling mill is the main equipment in the continuous rolling production line. It consists of cast steel gantry frame, rolls, frequency conversion motor reducer, gap adjustment system, electrical control system, feeding guard plate and roll surface cleaning mechanism.

The main function is to make the pole piece reach a suitable density under the rolling of the roller, and meet the pole piece thickness requirement according to the coating thickness.

Advantage:

The all-in-one machine can be used directly when it is powered on, and can be transported at any time without connection, after-sales, and debugging, which is more convenient than dispersing three pieces.

| Equipment configuration and parameters: | |

| Roll specification: | ∮210X330mm (roll surface diameter×roll surface width) |

| Operation mode: | continuous operation |

| Machine speed: | 5m/min |

| Type of pole piece or foil: | Battery pole piece |

| Appearance of the machine: | computer gray |

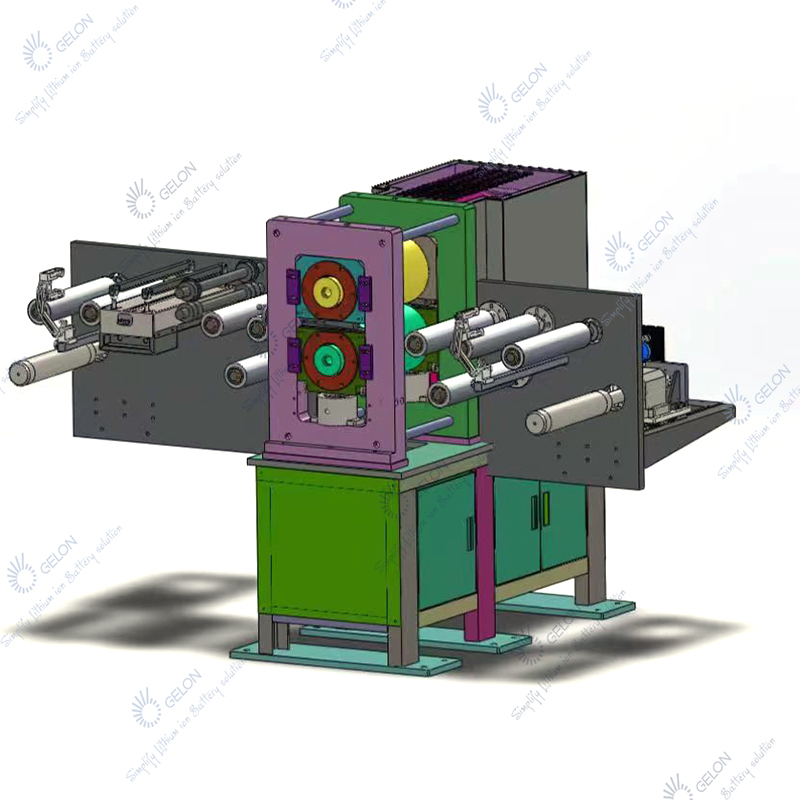

| 1. Host: | |

| Main function: | The pole piece reaches a certain thickness under the rolling of the roller |

| Roll specification: | ∮210X330mm (roll surface diameter*roll surface width) |

| Material: | 9Cr3Mo series high alloy cold rolled steel |

| Surface hardness: | above HRC66 |

| Depth of quenching layer: | ≥8mm |

| Roll chrome plating: | 0.08-0.12mm |

| Roll surface roughness: | Ra≤0.4 |

| Roll Gap Adjustment: | Manual Adjustment |

| Roll gap adjustment range: | 0~2.0mm |

| Maximum working pressure: | 80T |

| Equipment color: | computer gray |

| Roller heating method: | The closed-loop control heating system is composed of temperature controller, solid state relay and K-type thermocouple. |

| Heating power: | 1.6KW*2 (one upper and one lower roller) |

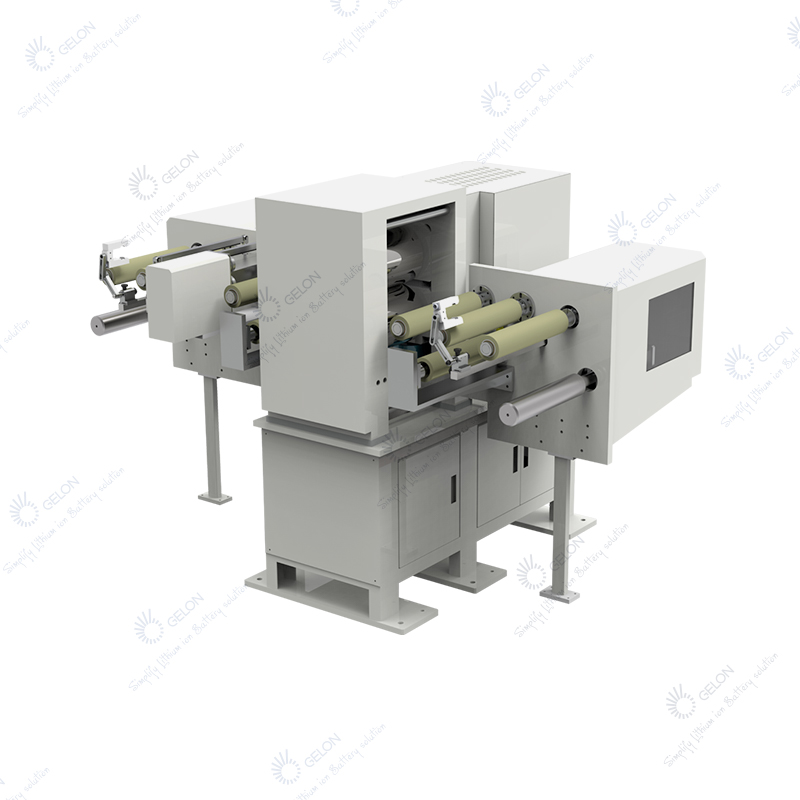

| 2. Unwind | |

| Unwinding shaft: | air shaft with control valve, equipped with air gun |

| Specifications: | 3inches *350mm |

| Pole Piece Tension Control: | Magnetic Powder Brake |

| Guidance control: | linear bearing guide |

| 3. Trimming | |

| Function: | It is used to cut the uncoated foil on both sides of the pole piece to reduce the pole piece wrinkle caused by the inconsistent elongation rate during rolling, and reduce the scrap rate caused by the pole piece strip. |

| Principle: | The upper cutting blade feeds manually, leans against the knife, and the left and right cutters are controlled separately. |

| Drive: | The frequency conversion motor drives the lower cutter shaft to be consistent with the rolling speed. |

| 4. Rewind | |

| Function: | winding the rolled pole piece material on the mandrel |

| Rewinding shaft: | air shaft with control valve equipped with air gun |

| Specifications: | 3 inches*350mm |

| Pole Piece Tension Control: | Magnetic Powder Brake |

| Guidance control: | linear bearing guide |

| Drive: | Drive the reel through the motor reducer and magnetic powder clutch |