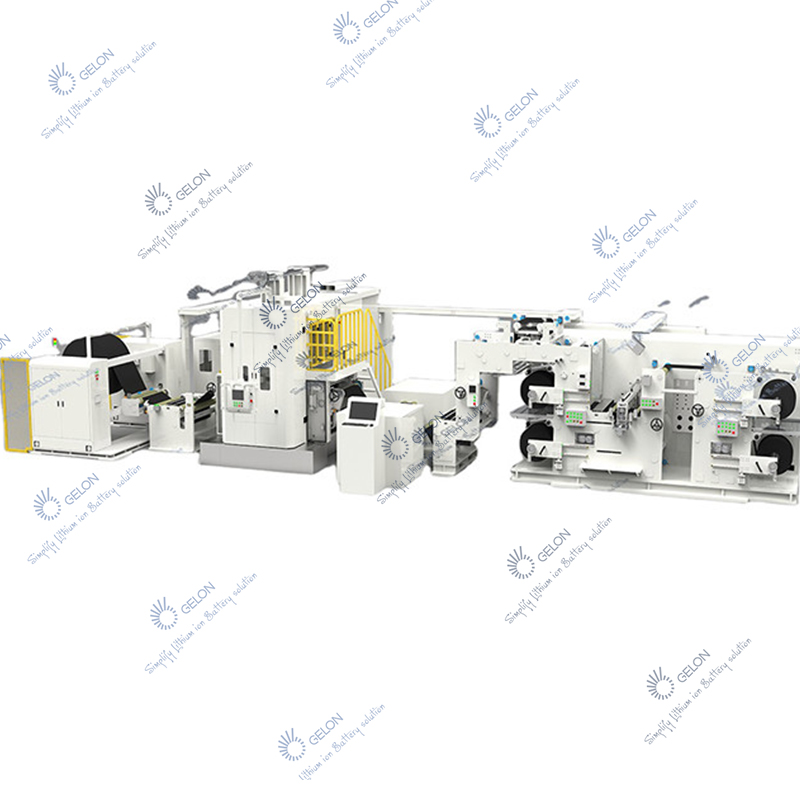

Automatic Intermittent coating machine

5.0

Read 266 reviewsApplication :It is used for intermittent or continuous coating of battery cathode and anode electrode , suitable for a variety of material systems.Coating structure: unwinding mechanism, coating head, drying oven, winding mechanism, control system, machine tail.Specifications:1) Coating method: cont

17 people are viewing this right now

Application :It is used for intermittent or continuous coating of battery cathode and anode electrode , suitable for a variety of material systems.

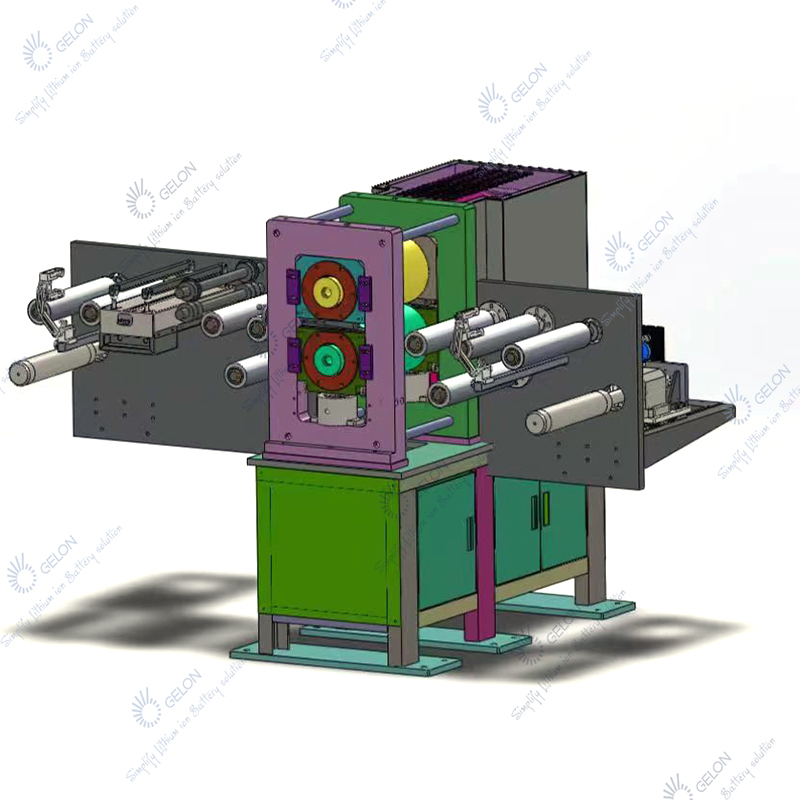

Coating structure: unwinding mechanism, coating head, drying oven, winding mechanism, control system, machine tail.

Specifications:

1) Coating method: continuous coating and intermittent coating

2) Foil specifications:

Thickness: Aluminum foil (AL): 11~30μm. Copper foil (Cu): 7~30μm

Width: Aluminum foil (AL): 280~620mm Copper foil (Cu): 280~620mm

3) Slurry viscosity: 1000~10000 cps

4) Coating thickness: 50-150um (single side dry thickness)

5) Coating width: 280-600mm

6) Intermittent length: more than 5mm

7) Length of pole piece: more than 50mm

8) Coating speed: 0.5~8m/min (related to the characteristics of the slurry system)

9) Oven: 18 meters (2 meters/section, 9 sections in total)

10) The temperature in the drying tunnel: Max150℃, the temperature difference in the single oven is ≤±5℃, the accuracy is ±1℃