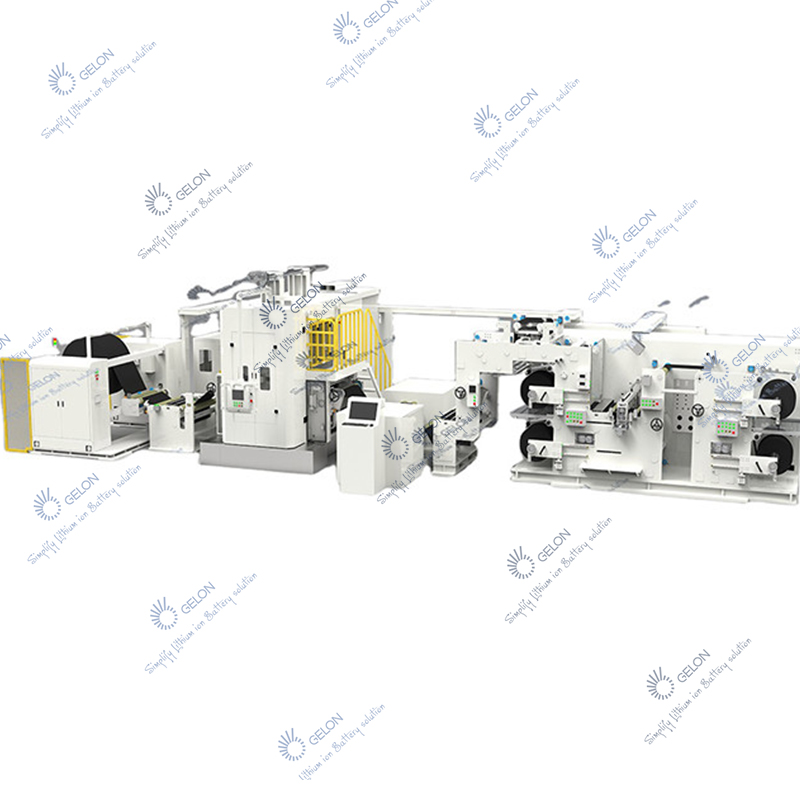

Large compatible semi-automatic stacking machine

5.0

Read 125 reviews1. This machine is specially designed for large square lithium-ion batteries and adopts the Z-shaped stacking method. The equipment realizes manual loading, subsequent electrode position correction and fully automatic stacking process. Different sizes can be achieved by adjusting the fixture, which is suitable for the development and sample production of stacked lithium-ion batteries2. The equipment adopts a single cantilever structure design, automatic servo tension control of roller separation materials, and automatic deviation correction control

17 people are viewing this right now

Equipment Overview

1. This machine is specially designed for large square lithium-ion batteries and adopts the Z-shaped stacking method. The equipment realizes manual loading, subsequent electrode position correction and fully automatic stacking process. Different sizes can be achieved by adjusting the fixture, which is suitable for the development and sample production of stacked lithium-ion batteries

2. The equipment adopts a single cantilever structure design, automatic servo tension control of roller separation materials, and automatic deviation correction control

Equipment Features

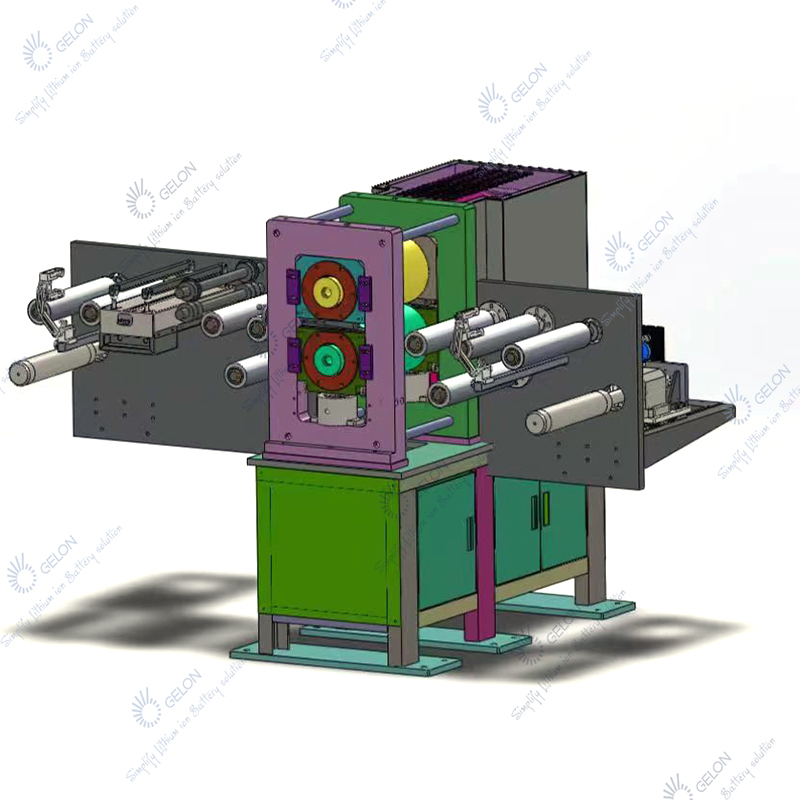

1. Z-shaped automatic stacking, automatic servo constant tension control of the diaphragm. Figure 1 is the stacking table adjustment, Figure 2 is the positive and negative electrode adjustment, Figure 3 is the automatic unwinding diaphragm, and Figure 4 is the suction cup adjustment

2. The number of stacks is automatically counted, manually reset to zero, and a digital display counter is designed. Automatic photoelectric deviation correction control of the diaphragm

3. The cylinder action is controlled by a button switch and PLC drive

4. The pole piece is placed manually, and the fixture assists in positioning to ensure the uniformity of the stacking

5. The compatibility design is adopted to meet the requirements of different battery cell size changes

name | parameter | Remark |

Lamination Type | Z-shaped lamination | |

Width of guide roller | 220mm | |

Substrate width | Max.200mm | |

Diaphragm core | 3 inches | |

Diaphragm roll diameter | Max.200mm | |

Stacking speed | 2-6S/piece (typical value) | Freely set according to needs |

Lamination thickness | Max.20m | |

Stack size | Length 56-200mm, width 45-160mm (Including lug size) | According to the size provided by customers Custom fixtures |

Lamination accuracy | ≤±0.5mm | Relative position and size between pole pieces |

Gas source | 0.5~0.8MPa argon, nitrogen (inside the glove box), or 0.5~0.8MPa compressed air | The equipment is placed in the glove box for use Then you must use argon or nitrogen source. Equipment placed outside the glove box can use compressed air |

power supply | AC220V/50Hz, AC110V/60Hz | Customized according to customer needs |

power | 1500W | |

Device size | About L1040*W840*H1210mm | |

Wooden box size after equipment packaging | About L1190*W990*H1400mm | |

Equipment Net Weight | About 410kg | |

Equipment gross weight | About 445kg | |

Warranty period | 1 year warranty, lifetime maintenance |