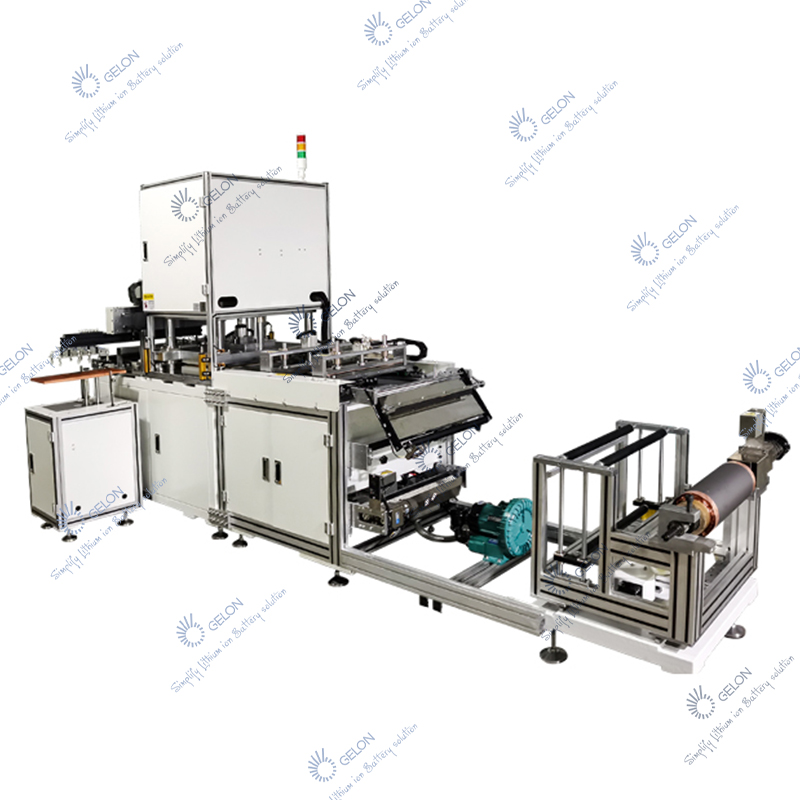

Automatic Die Cutting Machine

5.0

Read 607 reviewsThis equipment is a electrode piece automatic continuous die-cutting structure, roll electrode feeding, automatic unwinding, automatic correction, adjustable tension, automatic waste collection (with waste collection box, the waste after punching is directly dropped Into the waste box), manual unloading device, suitable for lithium-ion battery electrode cutting, only need to select the function in the program.

17 people are viewing this right now

This equipment is suitable for punching positive and negative electrodes of pouch cell battery. It is used in the front process of stacking machine. The speed is fast, the burr is less and the powder is very little dropped. Feed material is roll material, punching out of the electrode PET film automatic output, automatic cutting, manual collection. This die cutting machine has: electrode piece unwinding and rectifying device, electrode piece PET synchronous feeding device, precision punching device, waste collection device.

1.Technical parameters

1. Die-cutting elctrode pieces of different sizes, only need to replace the punching knife, which is convenient and cost-saving;

2. electrodepiece punching efficiency: 20-30/min

3. Life of punching knife: >15,000 times;

4. The man-machine interface has setting parameters for the number of electrodepieces, with error display prompt function; automatic counting function;

5. Relying on the sensor to accurately detect the positioning of the blank position, automatically eliminate the accumulated error of the electrode piece coating; the positioning accuracy is ±0.5 mm

6. The maximum laser knife mold template: width 500x length 400mm, suitable for 300*100mm, 150*100mm electrode pieces.

7. The qualification rate of equipment products: ≥98% (bad products caused only by this machine);

8. Equipment utilization rate: ≥95%

9. Applicable knife mold type: laser knife mold

2.Working principle

This equipment is a electrode piece automatic continuous die-cutting structure, roll electrode feeding, automatic unwinding, automatic correction, adjustable tension, automatic waste collection (with waste collection box, the waste after punching is directly dropped Into the waste box), manual unloading device, suitable for lithium-ion battery electrode cutting, only need to select the function in the program.

1.The electrode roll material unwinding adopts the active unwinding mode, which is controlled by the proximity switch, and the fitting pressure roller is installed to prevent the roll material from separating.

2.The photoelectric correction actuator is adopted to make the material conveyed steadily and ensure the accuracy of the feeding degree.

3. Single-seat high-speed forming machine seat, the knife seat is driven by the motor crankshaft, the main traction is driven by a high-precision servo motor to ensure the accuracy of the feeding translation, and the main traction roller is made of anti-corrosion rubber roller materials.

4. PLC program control, touch screen can set stepping accuracy and forming fixed number parameters (manual collection has no electrode material box collection mechanism).

3.Main Part Name

Electrode discharge mechanism

Electrode discharge correction

Electrode tension mechanism

Electrode and PET feeding

Punching mechanism

Waste collection agency

PET brush powder dust removal mechanism

Electric control system

4.Equipment parameters

Mechanical parameters | Cutting accuracy (mm) | ±0.15mm | |

Feeding accuracy | ≤0.5mm | ||

Transverse correction accuracy | ±0.5mm | ||

Template planarity | ±0.03mm | ||

Burr length (mm) | ≤30 | ||

Efficiency (ppm) | 20-30/分 | ||

Knife distance | Based on customer die requirement | ||

Tension control mode | Tension Motor Control | ||

Control precision | ±0.5mm | ||

Knife size | Max 500*400mm,customized according to customer requirements | ||

Material parameters | Electrode | Length (mm) | Roller |

Width (mm) | ≤300 | ||

Thickness (mm) | 0.06-0.3 | ||

Other | Dimensions of equipment(mm) | 4800*2000*1800 | |

Weight(kg) | 1300 | ||

Voltage | Single phase AC380V,6KW voltage fluctuation range :±10 per cent | ||

Power(KW) | 6 | ||

Die cutting pressure | ≥10T | ||

Compressed air | 0.4~0.6Mpa Compressed air per unitE | ||