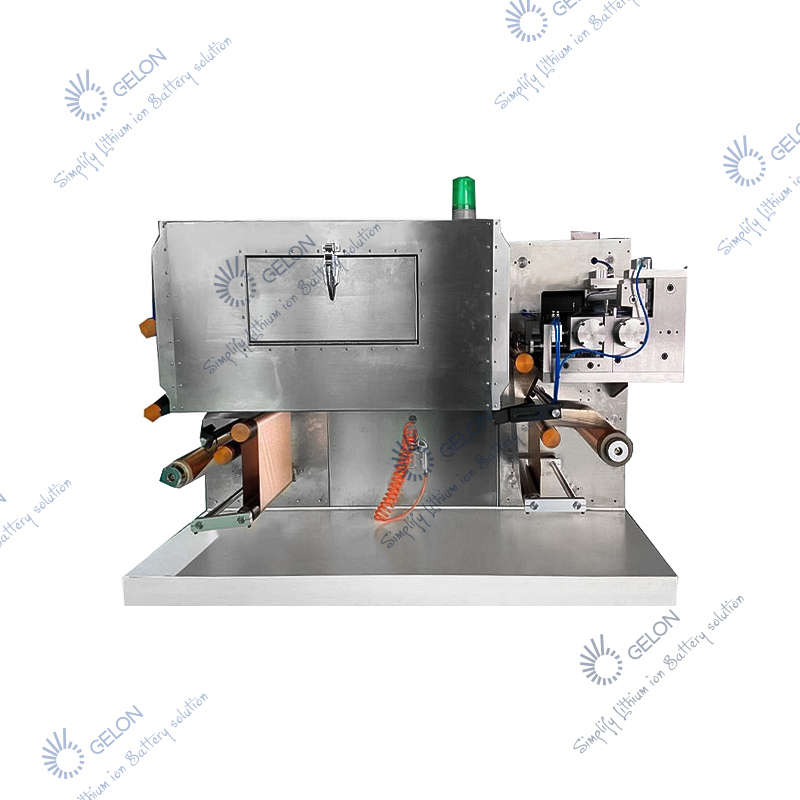

Intermittent Lab Coating Machine

5.0

Read 301 reviewsThe intermittent lab coating machine is a three-roll transfer coating equipment, which can be used for continuous and intermittent coating. It is convenient to be used in the surface coating process of various substrates. Especially in the lithium ion battery industry, the equipment is convenient fo

17 people are viewing this right now

The intermittent lab coating machine is a three-roll transfer coating equipment, which can be used for continuous and intermittent coating. It is convenient to be used in the surface coating process of various substrates. Especially in the lithium ion battery industry, the equipment is convenient for researchers to use, while meeting the requirements of coating accuracy and consistency is the same as the design of production, drying effect is excellent, is lithium ion batteries, super capacitors, Ideal choice for nickel batteries and other secondary battery R & D and small trials.

Feature:

1. Can freely switch to realize continuous and intermittent coating;

Base material tension control, stable strike-band, and equipped with rectifying devices;

Hot-air oven, blowing on top and bottom, with good drying effect;

Three roll transfer coating with wider coating windows;

Comma scraper metering, with precision adjustment mechanism, to obtain high coating accuracy;

PLC control, touch screen operation, easy to use;

Alternative solvent recovery treatment units;

Index:

| No. | Project | Technical parameter | Remark |

| Suitable system | Positive and negative electrode coating process of Lithium Iron Phosphate, Lithium Cobalt, LiMnO4, etc. | ||

| Operating substrate thickness | Al: 11~30um Cu: 8~30um | ||

| Roll design width | 330 mm | ||

| Guaranteed coating width | Within 300mm | ||

| Equipment mechanical running speed | 1m/min | ||

| Equipment coating speed | 0.3m/min | Depending on the drying condition | |

| Suitable viscosity of slurry | 2000~12000 Cps | ||

| Single side coating dry thickness range | 50-150μm | ||

| Minimum intermittent length | 5mm | ||

| Multistage minimum coating length | 20mm | ||

| Solvent properties | NMP(s.g=1.033,b.p=204℃) | ||

| H2O/NMP(s.g=1.000,b.p=100℃) | |||

| Suitable solid content | Cathode S.C. 60%±5% | ||

| Anode S.C. 50%±5%(PVDF system) S.C. 50%±5%(SBR system) | |||

| Proportion | Cathode 1.5—2.59/cm2 Anode 1~1.89/cm2 | ||

| Coating mode | Bilayer front and back 3 different spaced intermittent transfer coating / second side automatic tracking / continuous transfer coating | ||

| Base material running direction | Forward coating, substrate positive, reverse empty foil operation |