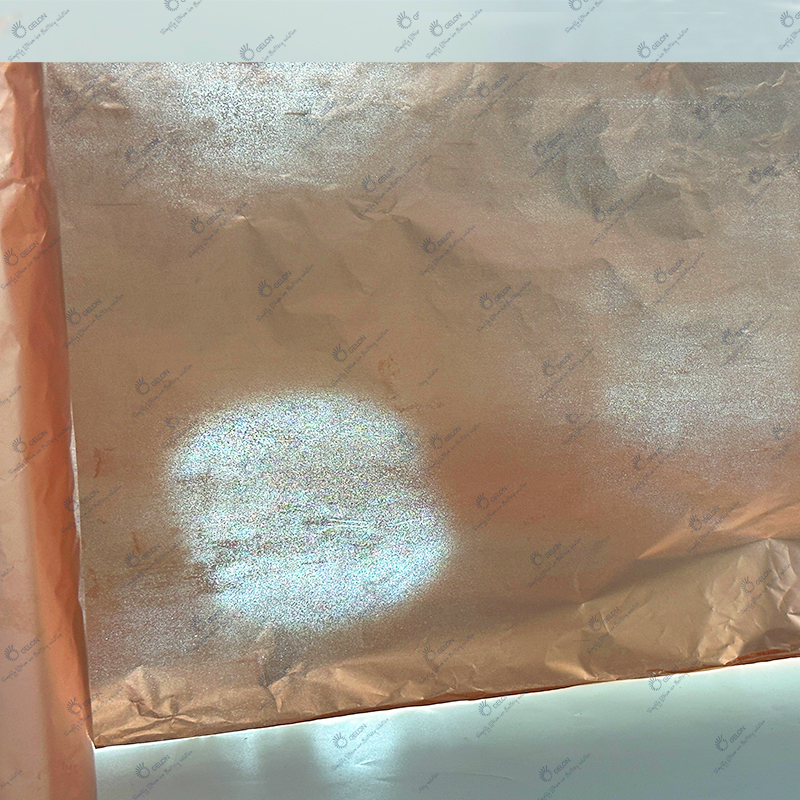

Microporous Copper Foil

5.0

Read 895 reviewsNew type of current collector: Secondary processing is performed on the basis of the original lithium battery foil, and holes are made by mechanical processing, which can maximize the maintenance of the physical and chemical properties of the foil itself. Used in lithium ion batteries, super capacit

17 people are viewing this right now

New type of current collector: Secondary processing is performed on the basis of the original lithium battery foil, and holes are made by mechanical processing, which can maximize the maintenance of the physical and chemical properties of the foil itself. Used in lithium ion batteries, super capacitors, lithium ion capacitors, etc.

Microporous Copper Foil Specification

| Item | Unit | Micro hole copper foil |

| Series | % | Red copper 99.9 |

| Thickness | mm | 0.006-0.020 |

| Surface density | g/m2 | Customized |

| Width | mm | 0-1000 |

| Hole density | PCS/cm2 | 4000-6000 |

| PCS/cm2 | 6000-8000 | |

| PCS/cm2 | 8000-10000 | |

| PCS/cm2 | 10000-12000 | |

| PCS/cm2 | 12000-15000 | |

| Hole consistency | % | 80-90 |

| Strength of extension | Mpa | 200-260 |

| Extend rate | % | 1.1~2.42 |

| specific resistance | μΩ.cm | GB/T228.1-2010 |

| wettability | Dyne value | 40 |

Microporous Copper Foil structure mode

1. Full surface micro hole aluminum foil/micro hole copper foil: no side wall for full-width

2. Retaining micro hole aluminum foil/micro hole copper foil: According to the battery design, it can meet the needs of the retaining. It can be divided into the following three types: can be divided into the following three types: both sides can be blocked, both sides + middle ribs, multi-wide ribs

Technical requirements for ribs: In ribs series products, the density of micro hole in the ribs should be less than 10% of the effective hole density.