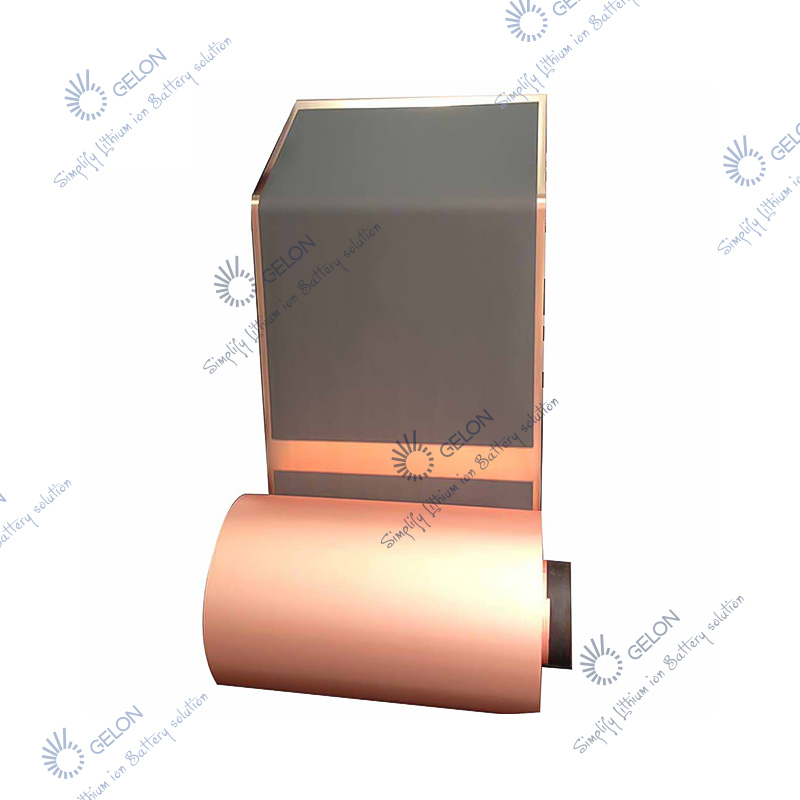

Carbon Coated Copper Foil

5.0

Read 718 reviewsConductive carbon coated copper foil can replace conventional Al foil as better anode substrate with improved properties.----Better electrical conductivity and less internal resistivity----Better mechanical strength and toughness to avoid short circuit caused by dendrite growth----Better coating str

17 people are viewing this right now

Conductive carbon coated copper foil can replace conventional Al foil as better anode substrate with improved properties.

----Better electrical conductivity and less internal resistivity

----Better mechanical strength and toughness to avoid short circuit caused by dendrite growth

----Better coating strength with electrode material

----Therefore, it will provide larger discharging capability and longer service life for Li-Ion batteries

Technical specification of coated carbon copper foil

| No. | Item | Standard | Testing | |

| 1 | Cu purity | % | ≥99.8 | ≥99.95 |

| 2 | Penetration hole | piece | No | No |

| 3 | Single-sided carbon coating quality | g/㎡ | Copper areal density +0.65 | Copper areal density +0.65 |

| 4 | Double-sided carbon coating quality | g/㎡ | Copper areal density +1.3 | Copper areal density +1.3 |

| 5 | Mass resistivity | Ω.g/㎡ | ≤0.17 | 0.168 |

| 6 | Thickness tolerance | um | 1 | 1 |

| 7 | Tensile strength | kg/㎡ | ≥30 | 35 |

| 8 | Room temperature elongation | % | ≥3.5 | 4.2 |

| 9 | High temperature elongation | % | ≥4.0 | 5.5 |

| 10 | Roughness (RA) | um | ≥0.4 | 0.7 |

| 11 | blank on both sides | mm | 15 | 15 |

| 12 | Wrong position | mm | ≤1 | 0.1 |

| 13 | Dyne | dyne | ≥40 | 55 |

| 14 | Adhesion (3M tape tearing) | OK | OK | |

Note: The specification value refers to IPC-4562, which is a general industry standard.