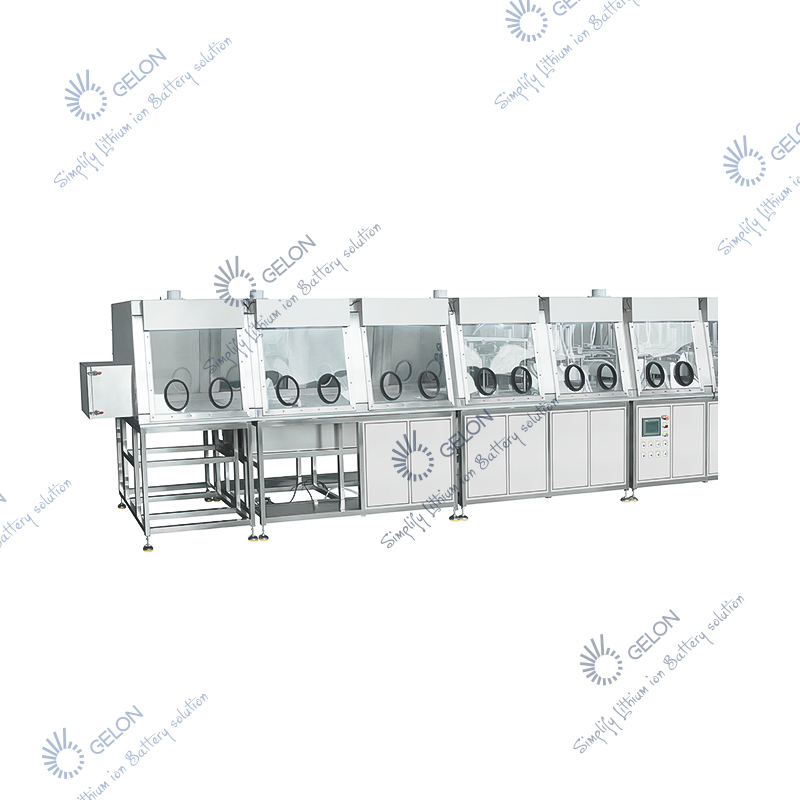

Cylinder Battery Automatic Filling Machine

5.0

Read 317 reviewsEquipment application:It is mainly used for liquid injection, cap welding and vacuum standing integrated in-line equipment for cylindrical batteries. Only need to manually load and lower the pallet, and the other process equipment is automatically completed. The machine includes a glove box, five se

17 people are viewing this right now

Equipment application:It is mainly used for liquid injection, cap welding and vacuum standing integrated in-line equipment for cylindrical batteries. Only need to manually load and lower the pallet, and the other process equipment is automatically completed. The machine includes a glove box, five sets of liquid injection systems, and seven sets of vacuum static systems.

1. The main components of the liquid injection system:

Liquid storage tank, X, Y axis liquid injection rack, 2.5g double-head liquid injection pump, liquid injection fixture, bus control system.

A. Configure 5 sets of liquid injection systems.

B. Double-head liquid injection pump, with a single injection volume of 0-2.5 g adjustable.

C. Equipped with liquid injection fixture, each tray can hold 196 batteries.

2. Basic parameters:

1. Working voltage: AC220V, power is about 1.5KW.

2. Applicable batteries: 18650, 21700, 26650, 32650 cylindrical batteries, single 196PCS/reel (other specifications can be customized).

3. Work efficiency: (MAX) 1.5-4K/H, (capacity depends on capacity).

4. Equipment size: (MAX) length 10m* width 1.2m* height 1.7m.

3. Technical parameters:

1. Double-head electric liquid injection pump:

A. Liquid output: 0--2.5g single time; (continuously adjustable).

B. Injection accuracy: ±0.03g.

2. XY axis injection system:

A. Working stroke (MAX): X-axis 200MM, Y-axis 200MM.

B. The working speed (MAX) moves 50 times/MIN per minute of the station gap.

3. Vacuum standing box:

A. Vacuum degree: -0.09 MPa.

B. Number of cycles: 0-5 can be set.

C. Pumping/resting time: 0~60min can be set.